“Many years ago, our father named a beautiful boat for my sister. Unfortunately that vessel sank and too did the name. I never thought that was fair. It was like my sister had been cheated somehow. I know if my father were still alive, he would have named another vessel for her. I am proud of the machines I build, much like my father was of his boat. I know my systems don’t float, or provide a steady platform for sunbathing in the gulf, but perhaps they should be named for my sister anyway. After all, there was enough pride in my father to name his vessel for this amazing woman. Like my sister, and that boat, I feel these machines are not only powerful, assertive and poised, but delicate and graceful at the same time. So be it then. I give you the Alyson.”

The idea:

The idea for these machines came while working on another design. A design I am still working on as a matter of fact. They are floor standing, rear horn loaded, transmission line speakers that I have been building for many years. The design has always been a challenge though. Don’t get me wrong, after 15 years of research and development, they are remarkable. The trick has been downsizing them into a real world size that can be aesthetically pleasing for, well; let’s just say the average spouse. (I hope I’m not in trouble here.) To do this, one must do a ton of dancing with the tuning of the machines. This takes time and patience. Both of which I am running out of. Often, I must take a break from the project and turn my attentions elsewhere. Call it a hiatus if you will. This is my way to get a fresh perspective when I return to the project. This also stands true for my other artistic endeavors. Stay tuned. They will be great indeed. Some day.

that I have been building for many years. The design has always been a challenge though. Don’t get me wrong, after 15 years of research and development, they are remarkable. The trick has been downsizing them into a real world size that can be aesthetically pleasing for, well; let’s just say the average spouse. (I hope I’m not in trouble here.) To do this, one must do a ton of dancing with the tuning of the machines. This takes time and patience. Both of which I am running out of. Often, I must take a break from the project and turn my attentions elsewhere. Call it a hiatus if you will. This is my way to get a fresh perspective when I return to the project. This also stands true for my other artistic endeavors. Stay tuned. They will be great indeed. Some day.

In the meantime:

About 5 years ago, several people asked if I had any smaller monitor designs. During this time, I had also noticed a trend toward smaller and simpler systems. In other words, more compact audio equipment that has less of a footprint on the living environment. Also around the same time, I had received a phone call from a studio where I had installed a set of my monitors many years ago. They had asked if I was still building and if I had made any improvements or updated the designs I had built for them. Truth is, I had thought about it many times, but the answer was no. I had not put thought to paper on these designs in a long while. Perhaps there was never a demand big enough to sustain building small near field monitors that cost as much as a Hyundai. Building one-offs specifically for the environment the client resides in was always my way. But alas, it may be time to open this can of worms again and see what I can do!

time, I had received a phone call from a studio where I had installed a set of my monitors many years ago. They had asked if I was still building and if I had made any improvements or updated the designs I had built for them. Truth is, I had thought about it many times, but the answer was no. I had not put thought to paper on these designs in a long while. Perhaps there was never a demand big enough to sustain building small near field monitors that cost as much as a Hyundai. Building one-offs specifically for the environment the client resides in was always my way. But alas, it may be time to open this can of worms again and see what I can do!

The research begins:

I spent several weeks in the shop revisiting the design I had built for the studio. I built a set identical to theirs and began tearing it down. I found so many flaws in the design, it was almost embarrassing. Not the overall sound mind you, just the overall lack of life and timbre. As a studio monitor these pieces were wonderful, but they would never pass the muster in a real world HI FI system. At least 10 times, “Clinical and flat” was scribbled in my listening notes. But that is what the client wanted! They wanted me to tune this system to sound like “NOTHING!” flat frequency response with as little coloration of their own as possible. The system they would be driving the monitors with was also as flat as it gets with no sugar coating what so ever. Spectral Audio amplifiers and preamps were chosen to feed the system from front to back. Flat, flat, flat…

Why did it sound so bad to me now? Why I ask?!?!

To me it all boiled down to two things. First; my lack of knowledge at the time of the original design execution. Second; the lack of technology at the time. The fast and silky capacitors of today simply did not exist. Nor did the amazing new foil inductors and Vishay resistors modern designers use now without a thought. Yes, back then the thought of spending 200 bones on a single capacitor was unheard of, but for a few

the time of the original design execution. Second; the lack of technology at the time. The fast and silky capacitors of today simply did not exist. Nor did the amazing new foil inductors and Vishay resistors modern designers use now without a thought. Yes, back then the thought of spending 200 bones on a single capacitor was unheard of, but for a few  manufacturers. Today, not so much. I’d spend 700 without a flinch if it is what it takes to get “That Sound”. And “That Sound” is exactly what I set my sights on. Don’t forget, the speakers in the studio were more than 10 years old now and permanently installed. I had to do this from 4,000 miles away. Challenge accepted!

manufacturers. Today, not so much. I’d spend 700 without a flinch if it is what it takes to get “That Sound”. And “That Sound” is exactly what I set my sights on. Don’t forget, the speakers in the studio were more than 10 years old now and permanently installed. I had to do this from 4,000 miles away. Challenge accepted!

I called the studio back a few months later and gave the news about the new crossover system. I made it clear that this may be just what they wanted. “Same system, just with new life and a powerful new sound”. I explained. They took the bait and off the crossover boards went to the FedEx shop down the street. It’s always hard to see your children off for the first time. Especially when some other technician will be in charge of the installation and final judgment. Studios don’t usually mess around and having their main monitors out of commission for two days is a BIG deal. So, cue the fingernail chewing Maestro!

the news about the new crossover system. I made it clear that this may be just what they wanted. “Same system, just with new life and a powerful new sound”. I explained. They took the bait and off the crossover boards went to the FedEx shop down the street. It’s always hard to see your children off for the first time. Especially when some other technician will be in charge of the installation and final judgment. Studios don’t usually mess around and having their main monitors out of commission for two days is a BIG deal. So, cue the fingernail chewing Maestro!

Shortly after I ran out of valium while waiting on the verdict, the call came. That call set the stage for what I decided to spend the next period of time and energy on. That time ended up being 5 years. “Josh, thank you! This system has never sounded as good. You really should build this design for the commercial market. It may work. How much do we owe you?” Let’s just say he was not as happy as he was when the phone call was initiated. None the less, he agreed it was still one hell of a bargain! Remember those $700 capacitors and inductors I mentioned earlier? I integrated a LOT of them.

Shortly after I ran out of valium while waiting on the verdict, the call came. That call set the stage for what I decided to spend the next period of time and energy on. That time ended up being 5 years. “Josh, thank you! This system has never sounded as good. You really should build this design for the commercial market. It may work. How much do we owe you?” Let’s just say he was not as happy as he was when the phone call was initiated. None the less, he agreed it was still one hell of a bargain! Remember those $700 capacitors and inductors I mentioned earlier? I integrated a LOT of them.

What next?

So, here we are. A few years later and several gray hairs to show for it, the Alyson AML is born. Of course, it’s true that a near field monitor retailing for the price of a Hyundai is still a narrow market. But when you tune that monitor to thrive in every real world environment outside of the studio, dress her in some pretty cabinetry, solid hardwoods, piano lacquers and the best components available, now we have something! A design within reach of most music lover’s pocketbooks. One that will also continue to thrill for years to come. You see, these are not just machines to me. They are instruments. Pieces of my industrial design should not be chosen like any other high-end speaker system. No, these are to be chosen as if purchasing a piano that will be in the family for generations to come. That is exactly what these are. Instruments. My pianos. Alyson.

So, here we are. A few years later and several gray hairs to show for it, the Alyson AML is born. Of course, it’s true that a near field monitor retailing for the price of a Hyundai is still a narrow market. But when you tune that monitor to thrive in every real world environment outside of the studio, dress her in some pretty cabinetry, solid hardwoods, piano lacquers and the best components available, now we have something! A design within reach of most music lover’s pocketbooks. One that will also continue to thrill for years to come. You see, these are not just machines to me. They are instruments. Pieces of my industrial design should not be chosen like any other high-end speaker system. No, these are to be chosen as if purchasing a piano that will be in the family for generations to come. That is exactly what these are. Instruments. My pianos. Alyson.

Technically speaking:

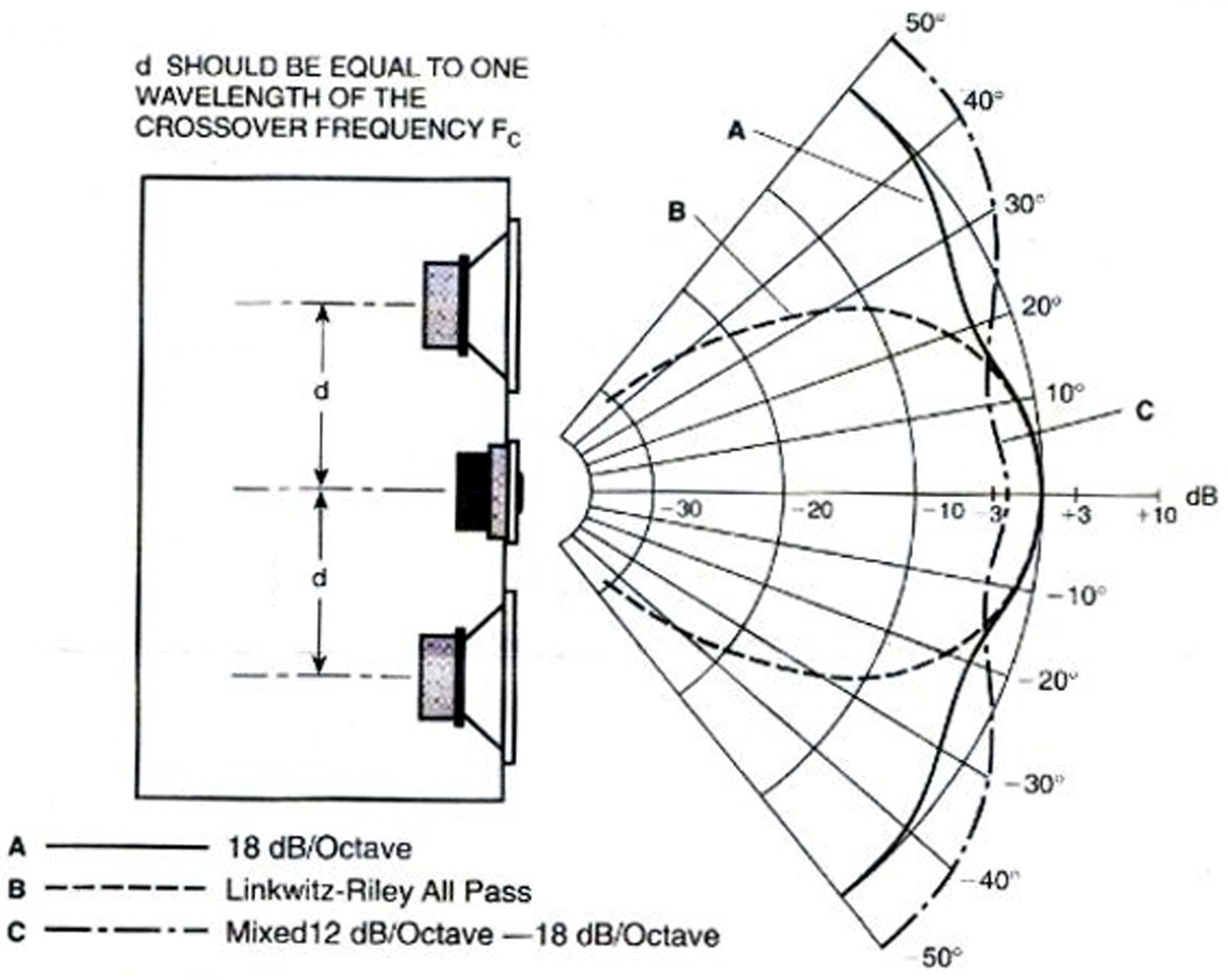

At first glance, The Alyson is a D'Appolito design. Inside it is a whole other ball game. Some call it a MTM, or Midrange – Tweeter - Midrange design. This design configuration was created by Joseph D'Appolito as a way of correcting the inherent lobe tilting of a typical mid-tweeter (MT) configuration, at the crossover frequency. I opted to spend the design hours and Doe-Ray-Me on a time-aligned configuration (Which is featured in all JWM designs). In this arrangement as is found in my smaller NET-1 design, the loudspeaker uses one shallow wave guide loaded driver, a mid-range (or mid-woofer/woofer) for the low frequencies and a shallow horn loaded, ring radiating tweeter for the higher frequencies, with the tweeter being placed above the other larger drivers. The configuration desires 3rd order (18 dB/oct or 60 dB/dec) crossover allowing the drivers to have similar horizontal dispersion, resulting in the absence of any sudden change in directivity with frequency.

At first glance, The Alyson is a D'Appolito design. Inside it is a whole other ball game. Some call it a MTM, or Midrange – Tweeter - Midrange design. This design configuration was created by Joseph D'Appolito as a way of correcting the inherent lobe tilting of a typical mid-tweeter (MT) configuration, at the crossover frequency. I opted to spend the design hours and Doe-Ray-Me on a time-aligned configuration (Which is featured in all JWM designs). In this arrangement as is found in my smaller NET-1 design, the loudspeaker uses one shallow wave guide loaded driver, a mid-range (or mid-woofer/woofer) for the low frequencies and a shallow horn loaded, ring radiating tweeter for the higher frequencies, with the tweeter being placed above the other larger drivers. The configuration desires 3rd order (18 dB/oct or 60 dB/dec) crossover allowing the drivers to have similar horizontal dispersion, resulting in the absence of any sudden change in directivity with frequency.

Since it is rare for a tweeter and mid-range (or woofer) to have their diaphragms or acoustic centers in the same physical plane, sound waves emitted by them (of the same frequency) will not reach a particular listening position in the on-axis plane at the same time. Conversely, the MT or TM combination's on-axis plane is not coincident with the physical on-axis plane - it is tilted w.r.t. the physical plane. (Say that 10 times as fast as you can.) The overall effect is that at the crossover frequency (when both drivers are reproducing the same frequency) the sound from both drivers does not acoustically sum ideally at the on-axis listening position. There will, however, be some off-axis listening position where the acoustic sum is ideal - but the listening position itself may be such that it is not practical. Thus, with a typical TM or MT loudspeaker where the drivers are not time-aligned, the main lobe is tilted away from the horizontal.

Since it is rare for a tweeter and mid-range (or woofer) to have their diaphragms or acoustic centers in the same physical plane, sound waves emitted by them (of the same frequency) will not reach a particular listening position in the on-axis plane at the same time. Conversely, the MT or TM combination's on-axis plane is not coincident with the physical on-axis plane - it is tilted w.r.t. the physical plane. (Say that 10 times as fast as you can.) The overall effect is that at the crossover frequency (when both drivers are reproducing the same frequency) the sound from both drivers does not acoustically sum ideally at the on-axis listening position. There will, however, be some off-axis listening position where the acoustic sum is ideal - but the listening position itself may be such that it is not practical. Thus, with a typical TM or MT loudspeaker where the drivers are not time-aligned, the main lobe is tilted away from the horizontal.

The direction in which the lobe tilts (i.e., the vertical orientation or angle of the lobe) is a function of the difference or offset between the acoustic centers of the two drivers. In order to remedy this effect, a great deal of measurement and listening must take place. Correcting the time alignment in JWM speakers is not necessarily to achieve a perfect dead center alignment. It is however, another tool in my box for tuning any given design to perform well in most rooms. How often do you sit directly in front of your speakers and perfectly in line with their acoustic center? Never you say? I know!

of the lobe) is a function of the difference or offset between the acoustic centers of the two drivers. In order to remedy this effect, a great deal of measurement and listening must take place. Correcting the time alignment in JWM speakers is not necessarily to achieve a perfect dead center alignment. It is however, another tool in my box for tuning any given design to perform well in most rooms. How often do you sit directly in front of your speakers and perfectly in line with their acoustic center? Never you say? I know!

So why MTM for the AML Josh?

Well, you would think when another mid-range or mid woofer is added vertically and symmetrically opposite to the existing one, the result is that the tilted on-axis plane gets corrected such that the differences between the mid woofer and tweeter planes become immaterial - the on-axis plane is always w.r.t. the tweeter's center. Sure, it makes sense all right. But, time is not always on our side.

The design requires that the two mid woofers are in exactly the same plane, and exactly the same distance from the tweeter - which is much easier to do physically than in the crossover. Up until recently, there has been a price to pay for this - although the MTM's on-axis response is near perfect, its radiation pattern or main lobe can be much narrower than that of the MT or TM configuration. As a result, the off-axis response (i.e., response at locations vertically away from exactly opposite the tweeter) should be much weaker. There can be obvious and discernible change in tonality at the crossover as one's listening height relative to the tweeter changes, and the effect is perceived more as the listener moves closer to the loudspeaker. In the Alyson AML and many other designs, this is corrected by (1) mounting the mid woofers as close to the tweeters as possible (so that the listening distance is much larger than the distance between the drivers) and (2) operating the mid woofers and tweeter in quadrature, i.e., achieved by ensuring that the tweeter lags the mid woofer by 90° in phase at the crossover frequency, and this in turn can be achieved if the crossover has a 3rd order Butterworth characteristic. To achieve the smallest distance between

The design requires that the two mid woofers are in exactly the same plane, and exactly the same distance from the tweeter - which is much easier to do physically than in the crossover. Up until recently, there has been a price to pay for this - although the MTM's on-axis response is near perfect, its radiation pattern or main lobe can be much narrower than that of the MT or TM configuration. As a result, the off-axis response (i.e., response at locations vertically away from exactly opposite the tweeter) should be much weaker. There can be obvious and discernible change in tonality at the crossover as one's listening height relative to the tweeter changes, and the effect is perceived more as the listener moves closer to the loudspeaker. In the Alyson AML and many other designs, this is corrected by (1) mounting the mid woofers as close to the tweeters as possible (so that the listening distance is much larger than the distance between the drivers) and (2) operating the mid woofers and tweeter in quadrature, i.e., achieved by ensuring that the tweeter lags the mid woofer by 90° in phase at the crossover frequency, and this in turn can be achieved if the crossover has a 3rd order Butterworth characteristic. To achieve the smallest distance between the mids and tweeters requires the drivers to have the smallest possible size - but there are design limitations to this (lowest mid-range frequency, for example, will place a lower limit to the mid's diameter). As you see in the Alyson AML, this small driver issue is not a problem, for there is a third way. (3) In conjunction with the other aforementioned methods, I also use the magic of wave guides and shallow horns to not only increase the width of the lobe, but much, much more. I can create a deeper stage effect, more focused dispersion pattern and a faster presentation. In addition the efficiency is increased substantially with the use of these wave guides. Voila!

the mids and tweeters requires the drivers to have the smallest possible size - but there are design limitations to this (lowest mid-range frequency, for example, will place a lower limit to the mid's diameter). As you see in the Alyson AML, this small driver issue is not a problem, for there is a third way. (3) In conjunction with the other aforementioned methods, I also use the magic of wave guides and shallow horns to not only increase the width of the lobe, but much, much more. I can create a deeper stage effect, more focused dispersion pattern and a faster presentation. In addition the efficiency is increased substantially with the use of these wave guides. Voila!

What is on the inside counts most:

I mentioned the inside of the Alyson AML being a whole other ball game. This is true. Not only does the shape play a crucial role in the design, so do the inside baffles, materials, and damping. In concert, (pun intended) the combination of all the above elements are tuned to the specific task of helping each other compress and release the back pressure of air within the cabinet. These elements must do so without one affecting the others performance through stray vibrations or standing waves within the interior chambers. This also is true of the driver components and electronics attached to the speakers. All work as one.

Let’s start with her curves baby:

There is a graceful curve to both the  Net-1 and Alyson AML. In almost all curved cabinet speakers, the initial idea is to avoid standing waves between parallel surfaces inside the cabinet. This is true in my designs. This is but one reason for my utilization of the concept. The curved design also allows me to compress the back wave of the drivers into separate band pass cham

Net-1 and Alyson AML. In almost all curved cabinet speakers, the initial idea is to avoid standing waves between parallel surfaces inside the cabinet. This is true in my designs. This is but one reason for my utilization of the concept. The curved design also allows me to compress the back wave of the drivers into separate band pass cham bers (two in this case) tuned to any frequency I desire. The most obvious drawback to most designers would be the speed of the rear exhaust being out of phase with the front of the speaker. You may have heard the effect in your average boom car going down the street. ONE NOTE BASS, SLOW AND OUT OF SYNC. Well, if you treat the port as an extension to the interior chambers and utilize it as a transmission line, it seems to speed things up and increase the overall efficiency of the lower frequencies! Voilà! What we have is a band pass transmission line design in a compact architecture. It gets way more complicated, but I’ll leave it at that for now.

bers (two in this case) tuned to any frequency I desire. The most obvious drawback to most designers would be the speed of the rear exhaust being out of phase with the front of the speaker. You may have heard the effect in your average boom car going down the street. ONE NOTE BASS, SLOW AND OUT OF SYNC. Well, if you treat the port as an extension to the interior chambers and utilize it as a transmission line, it seems to speed things up and increase the overall efficiency of the lower frequencies! Voilà! What we have is a band pass transmission line design in a compact architecture. It gets way more complicated, but I’ll leave it at that for now.

Make it beautiful inside and out:

I cannot stress enough the importance of the materials used in not only musical instruments, but musical speakers as well! After all, they do the same thing don’t they? At least they should. You would not expect a melamine violin to sound like the padauk one in first chair. Or a cardboard bass drum to have the same attack as the shaped maple beauty on the marching field. Thus, you will find no cardboard or melamine in my machines. What you will find is carefully chosen materials. These materials are selected for their damping abilities, resonant characteristics and so much more. My background in the visual arts and industrial design demand that materials I select must also sing to the eye. You would think it stops there, but no. Even the finish plays a crucial role in the overall sound of the machine. Just the specific lacquer used on a violin is crucial to its tone, so is true of the speaker. The bonus of this approach is obvious. The combination of art, audio and design create a product that will satisfy on a multitude of levels for many years to come.

Baffles, materials and taming the shrew:

Internally, all kinds of things take place that produce vibration and resonance. Some of these effects are desirable, some are not. I have spent a great deal of time deciding which should be exploited in my designs. I have spent equally as much energy in the pursuit of taming all of them with as little material as possible. Those materials are extremely important though. In some cases, even more essential than the cabinets themselves. Each has been selected from numerous manufactures for their ability to do precisely what I need them to do. No more, no less. Efficiency is the name of the game when taming resonance.

The curved cabinets and stand wing components are made from the same materials and finished in the same way as well. The reason for this was to create a symbiotic relationship between the stand and speaker cabinet. Both components have nearly the same mass and surface area, thus react to vibration in the same way. The shape of both allow for any unwanted stray resonance to be channeled silently down through the stand and terminate in the lower plate. In the rare case any further damping is required; the choice of spiked feet couples the units to the floor and bleeds the vibration away.

People and parrots like shiny things:

When it comes to the finish on the speakers and stands, I spare no expense. The bodies of the system and stand wings use a 12 layer process, followed by a 6 step polishing regiment. I utilize the latest conversion varnish technology. Each layer is sprayed, dried and sanded. The final coat is then sanded several times down to 3,000 grit. Next, final polishing begins. Polishing is also a labor of love and takes a minimum of 2 compounds before final polishing. This not only provides a durable and long lasting finish, it allows for a deep and rich mirror finish that rivals any piano manufacturer’s proprietary technique. The possibilities are endless as far as solid colors, but if the end user wishes, I can custom match any top finish with automotive lacquers and/or clear coated bases. As long as the damping factor of the coats fit within my acoustic parameters, I’m ready to play!!!

The hardwood components of these systems are treated in the same way. Hardwoods are picked first for their acoustic properties, then beauty. Form must follow function in this case, but in every case thus far, the two have worked together perfectly. The very same 12 step process is used in the finishing of the hard wood components. Rather than using pigmented primers and bases, as in the body and wings, I use crystal clear sanding and leveling materials to start. Again, each layer must be dried, sanded and inspected before the next. The end result is worth every bit of sweat. Don’t forget, I can create these in any hardwood you wish, as long as it fits within my parameters of the ideal acoustic wood. No, Balsa will not work! Lol…

The hardwood components of these systems are treated in the same way. Hardwoods are picked first for their acoustic properties, then beauty. Form must follow function in this case, but in every case thus far, the two have worked together perfectly. The very same 12 step process is used in the finishing of the hard wood components. Rather than using pigmented primers and bases, as in the body and wings, I use crystal clear sanding and leveling materials to start. Again, each layer must be dried, sanded and inspected before the next. The end result is worth every bit of sweat. Don’t forget, I can create these in any hardwood you wish, as long as it fits within my parameters of the ideal acoustic wood. No, Balsa will not work! Lol…

In the near future, I will be adding more visual options to each line of speakers. This will include custom veneers, hardwoods and a rainbow of colors to choose from. Depending on demand, I may also choose to keep custom automotive finishes on hand as standard practice. Stay tuned!

In the near future, I will be adding more visual options to each line of speakers. This will include custom veneers, hardwoods and a rainbow of colors to choose from. Depending on demand, I may also choose to keep custom automotive finishes on hand as standard practice. Stay tuned!

The bottom line of the Alyson AML:

My mission was threefold. First, to create a fast and efficient MTM design, utilizing a transmission line and band pass cabinet layout. Second, to provide many options to the end user in finishes and wood. Yes, a high “Wife Factor” coefficient is always a plus! There, I said it. They are easy on the eyes! Third, I believe it important to have my machines HAND MADE and manufactured in the USA! Yes, I have some parts made in Germany, Canada and Denmark, but I feel there is no manufacturer in the US for those certain parts, that can meet my demand for perfection. "YET"! As soon as that is possible, ALL of these systems in my collection will be made here at home in Hawaii. I feel satisfied that I have exceeded my objectives and confident that the listener will agree. As I said in the beginning of this post, These machines are to be picked as if they were a piano for your family. After all, I build them to last for many generations.

Alyson Aml...

Thank you,

Joshua W. Miles

Specifications: Frequency Response: 35-35,000Htz Short term max. power: 600 Watts Long term max. power: 450 Watts X-Over frequency: 2,500Htz Impedance: 4 Ohms Sensitivities: 89dB SPL Recommended amplifier: 40-400 Watts

Questions and Inquiries:

All questions and inquiries, including pricing can be directed to the fallowing addresses. All dealers are also welcome to call at any time. Systems will be available in person as well as at select locations in the very near future. Also, stay tuned for my personal on-line shop as well!

Joshua W. Miles Designs LLC PO BOX 944 Kailua, HI 96744 (808)349-6661 (808)421-9991 joshuawmilesdesigns@yahoo.com

Special Thanks:

I would like to send a special and warmhearted thank you to Thorben Wuttke. Owner and master woodworker for Honolulu Furniture Co. Without your MAD SKILLS and exceptional taste, these machines would still be just a scribble on a bar napkin. Much Mahalo!!!

References

- "Article by Rane discussing the Linkwitz-Riley crossover, time-alignment, lobing and correction of lobe tilt in TM or MT speaker configurations."

- "Biro Technology article showing lobe correction with MTM loudspeaker configuration, and other analyses"

- "Biro Technology article, section 3"